Transducers

CO-L

Technical specifications

- Pipe Diameter: 0.4 m to 15 m

- Pipe wall thickness: up to 100 mm (steel, plastic, glass fiber)

- Accuracy velocity: up to ± 0.5 % of reading

- Frequency: 200 kHz

- Beam width: 8° (-3dB)

- Material: stainless steel, polyamide

- Operating temperature: -20 °C to +60 °C

- Dimensions: 270 x 115 x 100 mm (L x W x H)

- Installation: from the outside of the pipe

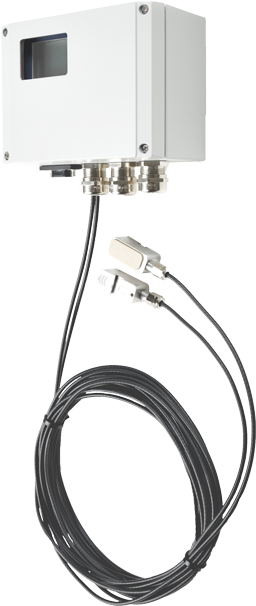

Ductus

Time of flight system with digital signal processing

Technical specifications

- Acoustic paths: 1 to 10 (more upon request)

- Range: ± 20 m/s (bidirectional)

- Accuracy Q: up to ± 0.15 % (10 paths)

- Repeatability: < ± 0.02 %

- Zero Stability: < 1 mm/s

- Communication: RS-485, Modbus RTU/TCP, Wireless LAN, Ethernet 10/100 Mbps, 4G (LTE) / 3G (HSPA+) / 2G

- Inputs: max. 4 x 4-20 mA, 2 x digital

- Outputs: max. 4 x 4-20 mA, 4 x relay, 2 x pulse

- Power supply: 9-36 V DC or 100-240 V AC (50/60 Hz)

- Approval: IP66 (NEMA 4)

- Enclosure: aluminium

DOWNLOADS

Transducers

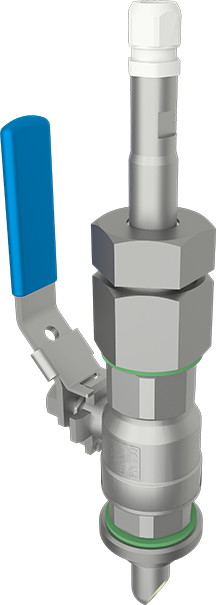

FT-S

Technical specifications

- Frequency: 1 MHz

- Beam width: 5° (-3dB)

- Configuration: IEC41 / ASME PTC 18

- Pipe diameter: 0.1 m to 2 m

- Mounting: welding socket or thread

- Pressure rate: 20 bar *

- Material: Stainless steel

- Cable: twisted pair with shield

- Operating temperature: 0° to +40°C (up to + 150 °C on request)

- Dimensions: Ø 1″, length: 293 mm

- Installation: incl. fixing device, ball valve and welding socket.

Pipe needs to be dewatered only for the time of initial installation. Designed to allow removal of the entire transducer for repair, replacement or cleaning without the need to dewater the pipe lation.

*) other ranges upon request

KATflow 100

Stationary Clamp-On ultrasonic flow meter

Specification

- Pipe diameter range 10 mm to 3000 mm

- Temperature range for sensors -30 °C to +80 °C (-22 °F to +176 °F)

- Weight 750 g

- Robust IP 66 aluminium enclosure

- Sturdy unit with LCD display and five-key keypad

- Wall or pipe mounted

Features

- Low cost of ownership

- Process outputs including RS 485, Modbus RTU and HART* compatible output

- PT100 inputs for heat quantity (thermal energy) measurement

- Bi-directional measurement with totaliser function

- Innovative installation wizard for quick and intuitive programming

- Configuration can be changed to suit customer requirements

Applications

- Water and wastewater measurements

- Replacement of electromagnetic flow meters

- Monitoring and controlling of Heating, Ventilation and Air Conditioning (HVAC) systems

- Cost-effective solution for large scale projects

- Automated process control

- Shipping applications